Stellar.net uses cookies to deliver the best possible experience to you. To continue using this website, you agree that we may store and access cookies on your device.

Facility Optimization Planning & Design Services

)

Eliminate unnecessary costs in your food manufacturing facility by following this list.

Designing fully optimized processing, distribution, and storage facilities internationally.

Expertise in a Range of Industries, Payback, & Worldwide Services

Stellar's optimization assessments and design-build solutions are helping clients worldwide improve their bottom line. Through comprehensive system analysis, we identify opportunities to provide the highest of quality, improve efficiency, and ensure your visions come to fruition. Our expertise spans numerous industries, including:

- Beef, pork, and poultry processing

- Dairy and beverage production

- Ready-to-eat and bakery products

- Produce

- Pet food

- Cold storage and distribution

- Pharmaceutical manufacturing

- Commercial applications

Our optimization assessments help you:

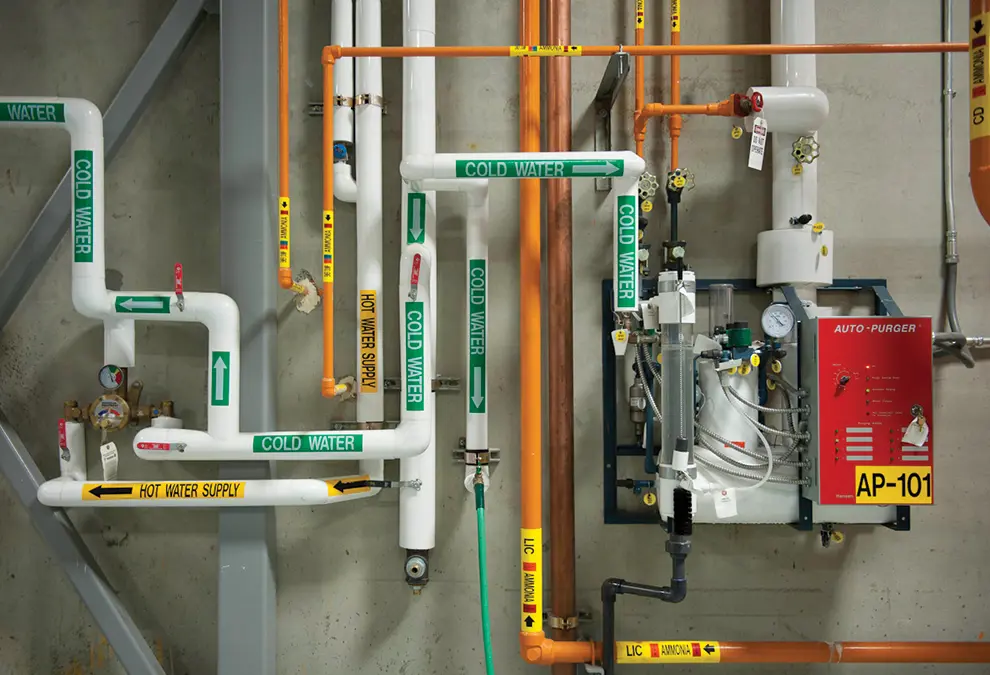

- Reduce utility consumption (water, air, gas, electricity, steam)

- Lower operating costs

- Improve process efficiency

- Extend equipment lifespan

- Reduce your carbon footprint

- Achieve regulatory and environmental compliance

We provide a structured approach:

- Analysis: Establish a baseline, identify improvement opportunities, and define goals.

- Direction and Estimates: Outline the scope of work and present various solutions with ROI estimates.

- Corrective Action: Prioritize actions, design, fabricate, and install solutions.

- Monitoring: Track and report results.

- Ongoing Maintenance: Access 24/7 service and preventive maintenance.

The tools you need to improve your food or beverage plant’s efficiency. Discover how a facility assessment can benefit your business, which specific areas to examine to save you money, and what to look for in an assessment partner.

Stellar's leadership has the expertise and understanding necessary to advise you, even on the most complex challenges.