Thermal & Building Envelope Construction Services

)

Inside the design, construction and philosophy of this one-of-a-kind award-winning plant.

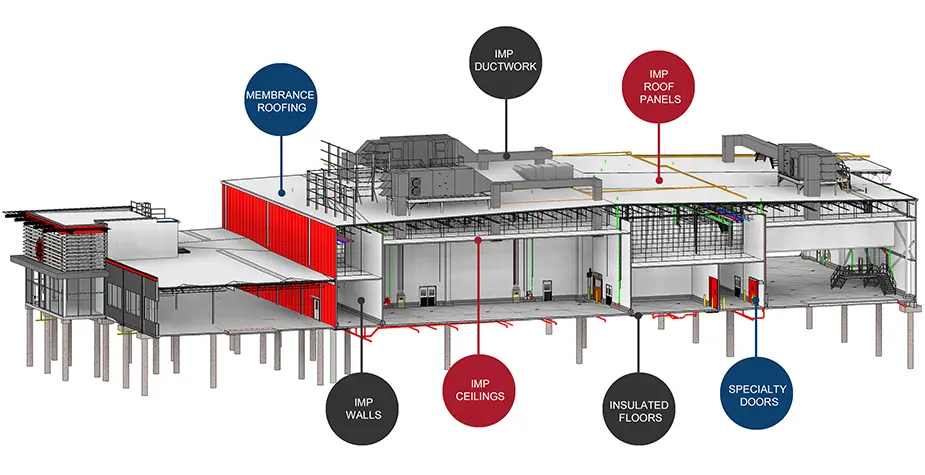

Thermal and building envelope services for unparalleled efficiency and food safety standards

Stellar’s team of experienced professionals boasts an average of over 20 years of cross-disciplinary expertise. We provide comprehensive building envelope services and work seamlessly with design and construction teams to conduct meticulous analyses of energy consumption and other critical factors. Through this process, we identify materials and techniques that ensure unparalleled efficiency, substantial cost savings, and meticulous adherence to food safety standards.

Our unmatched expertise has earned us a reputation as the go-to provider of building envelope services for prestigious markets and industry leaders. We forge lasting partnerships with our clients, who trust us to deliver outstanding results through years of successful collaboration.

Delivering high-quality installations, superior cost efficiency, and versatility

At Stellar, we take pride in our technicians, hiring and training them to deliver high-quality installations, superior cost efficiency, and tight deadlines. Our senior technicians possess advanced knowledge, which they pass on to new technicians during their training. We ensure that our technicians are versatile and capable of handling both wall and roofing tasks, allowing our teams to adapt as needed.

Vapor barrier integrity at Stellar: Construction of uncompromising integrity for low-temperature buildings

Stellar prioritizes the construction of a vapor barrier with uncompromising integrity. We meticulously install insulated panel walls, roofing, doors, and ductwork to form an integrated structure for buildings that require low temperatures, even as low as -40 degrees Fahrenheit.

Unmatched IMP Installation of Insulated Metal Wall, Roof, and Ceiling Panels

We conduct thorough evaluations of our clients' plant operations to determine the most appropriate door types and materials. We consider various criteria and characteristics, including activation method, budget constraints, space clearances, door construction, opening/closing frequency, operating conditions (temperature/humidity), daily operational routines, pressure differences, safety requirements, delayed closing, and intended usage.

IMP Ductwork for Greater Air Quality, Energy Efficiency, and Food Safety Standards

Our installation services for insulated metal panels (IMPs) are available in a wide range of colors, finishes, dimensions, and a variety of other unique options. Our panels come with finishes compliant with the United States Department of Agriculture (USDA), including siliconized paint, Plastisol, and Type 304 stainless steel. We are the largest purchaser of IMPs in the United States, having installed nearly 6 million square feet over the past five years. This allows us to offer competitive pricing to our customers.

We install IMP ductwork for its significant benefits over traditional materials, including improved air quality, energy efficiency, and durability. Most importantly, IMP walls promote food safety by providing a more sanitary finish that can easily be washed down and withstand harsh chemical cleaning. IMP walls also meet plant owners' need for a more sanitary surface at floor and curb levels.

Preventative Maintenance is Key to Long-Lasting Freezer Floors

Frost heave is a silent killer of freezer floors, and regular preventive maintenance of the underfloor heating system is essential to maximizing their lifespan. Neglecting this aspect can lead to detrimental consequences, such as frost formation in the subgrade soils, which can result in raised, cracked floors. These problems can give rise to safety hazards, operational disruptions, and even severe structural damage. Addressing frost heave promptly is paramount, as the longer it goes unattended, the greater the potential for escalating damage.

Why Stellar?

Stellar is committed to providing exceptional services that ensure optimal efficiency, cost savings, and food safety. Our dedication to vapor barrier integrity and the use of IMPs allow us to provide unmatched solutions for low-temperature buildings, while our commitment to our clients ensures lasting partnerships built on trust and successful collaboration.

Stellar's leadership has the expertise and understanding necessary to advise you, even on the most complex challenges.