Facility Optimization Planning & Design Services

)

Eliminate unnecessary costs in your food manufacturing facility by following this list.

Designing fully optimized processing, distribution, and storage facilities internationally.

Expertise in a Range of Industries, Payback, & Worldwide Services

Our team consists of experienced engineers who offer optimization assessments and design-build solutions worldwide. We've helped our clients in a range of industries, including beef, pork, poultry, dairy, beverage, ready-to-eat, bakery, cold storage and distribution, pharmaceutical, steel, and commercial applications, improve their efficiencies. By following our recommendations and making modifications, many of our clients achieve payback in only a few months.

Stellar’s optimization assessments can help you:

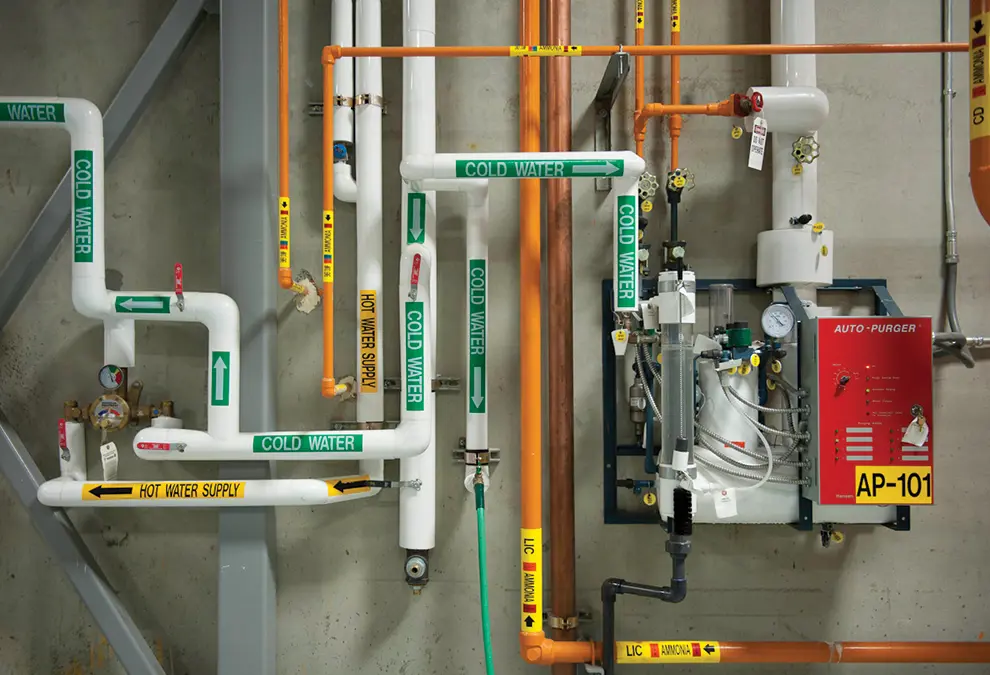

- Reduce consumption of all utilities — water, air, gas, electricity, and steam

- Reduce operating costs

- Improve process efficiencies

- Prolong equipment life

- Reduce carbon footprint

- Achieve regulatory and earth-friendly sustainable compliance

The tools you need to improve your food or beverage plant’s efficiency. Discover how a facility assessment can benefit your business, which specific areas to examine to save you money, and what to look for in an assessment partner.

Stellar's leadership has the expertise and understanding necessary to advise you, even on the most complex challenges.